CLIENT NEED

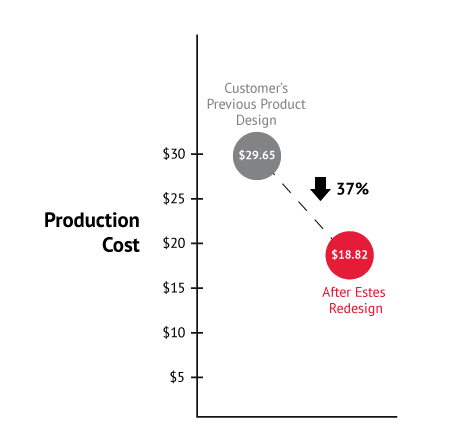

The original design of a client’s steel pan used in a medical application was a three-piece spot-welded assembly that cost $29.65 to produce.

SOLUTION

To increase the manufacturing efficiency, the Estes team moved the production from the press brake equipment to their Salvagnini forming cell. The three components were consolidated into one complex part that had twelve bends.

RESULT

The redesign eliminated several secondary operations and reduced the overall production cost to $18.82, a 37% savings.