Estes Design and Manufacturing is ISO 9001 Certified.

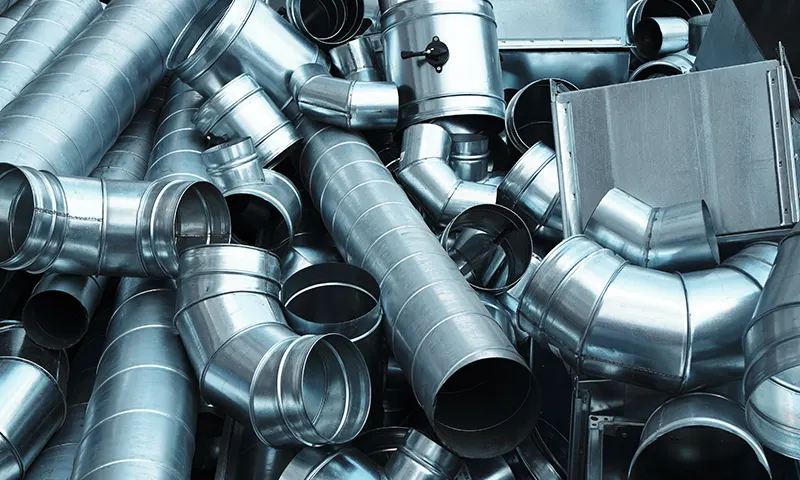

As a leading manufacturer of sheet metal parts and components for the HVAC and appliance industries, we work with multiple material types at the highest level of precision and expertise.

The core of our operation is diversity in equipment, technology, and innovation. This allows us to offer tailored solutions with unmatched flexibility and reactivity. At Estes, we don’t just manufacture sheet metal parts and components; we forge partnerships and deliver excellence.