Advanced Technology Improves Your Speed to Market

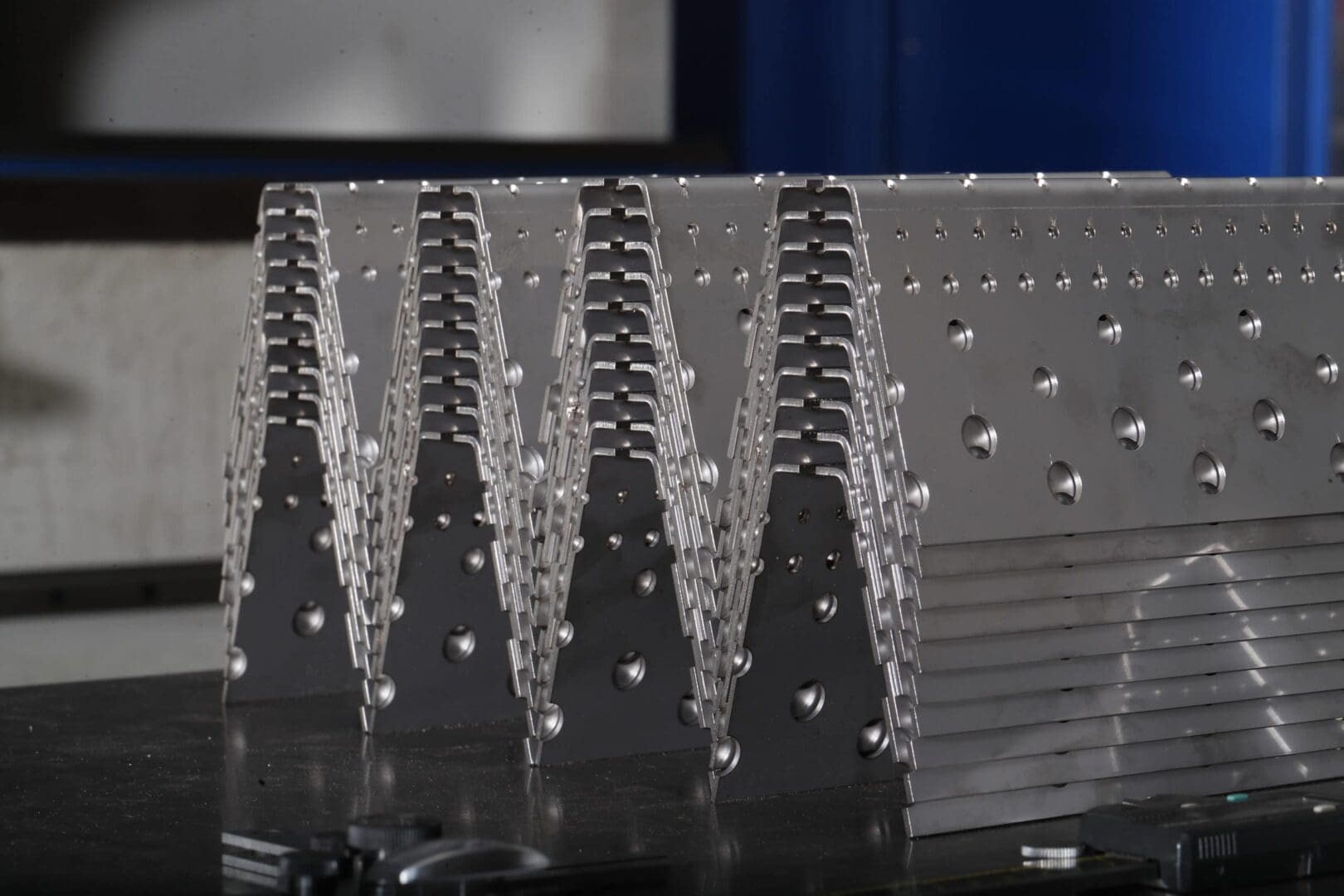

Rapid Sheet Metal Product Development & Prototyping Services

SPEED TO MARKET | REDUCED COSTS | INNOVATIVE DESIGN

Who We Serve

Estes Accelerator Product Development and Prototyping Services are an ideal fit for established companies looking for a partner to manage new or revised product designs and development. We can:

- Manage the complete product design and development process

- Optimize designs for manufacturability and assembly

- Value engineer products to ensure cost-effective manufacturing

- Produce and refine prototypes from existing designs

- Transition products into full production

- Provide short-run manufacturing for quantities less than 50

Advantages of Estes Accelerator

Reduced Costs

With state-of-the-art technology at our disposal, our product development team designs around our unique fabricating technology that utilizes speed and automation to drive down costs.

Value Engineering

Our design team draws on their manufacturing expertise to evaluate your part, looking for ways to reduce manufacturing costs and to simplify assembly (DFMA) throughout the development process.

Innovation & Creativity

Our team of experienced engineers challenge modern methods and seek for ways to improve on current fabricating processes. Innovation is at the core of everything we do.

Reduced Lead-Times

Time is money, and waiting means waste. Estes Accelerator is designed to give customers quick turnaround on all of their projects and improve speed to market.

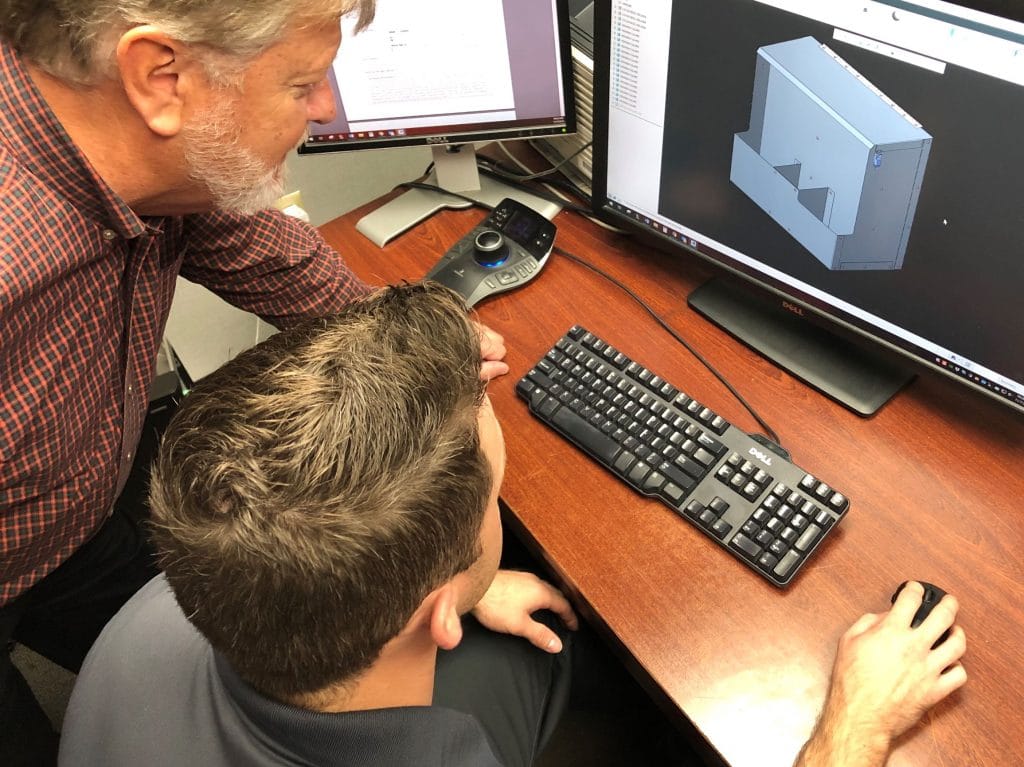

Estes Accelerator - Product Development

Estes Accelerator Product Development is comprised of a team of engineers and designers with decades of sheet metal fabricating experience and knowledge of best practices who are focused on the most economical design.

What Can Estes Accelerator's Product Development Services Do For You?

- Manage the complete product design and development process

- Serve as a resource to your design staff

- Optimize designs for manufacturability and assembly (DFMA)

- Value engineer products to ensure cost-effective manufacturing

- Provide manufacturing expertise, helping designers translate ideas from the drawing board to the assembly line

- Ensure that a product can be manufactured efficiently while maintaining its aesthetic and functional purposes.

- Model new designs in Pro E, SolidWorks, or AutoCad Inventor

What are the benefits of Estes Accelerator's Product Development services?

Reduced Costs

With state-of-the-art technology at our disposal, our product development team designs around our unique fabricating technology that utilizes speed and automation to drive down costs.

Innovation & Creativity

Our team of experienced engineers challenge modern methods and seek for ways to improve on current fabricating processes. Innovation is at the core of everything we do.

Value Engineering

Our design team draws on their manufacturing expertise to evaluate your part, looking for ways to reduce manufacturing costs and to simplify assembly (DFMA) throughout the development process.

Reduced Lead-Times

Time is money, and waiting means waste. Estes Accelerator is designed to give customers quick turnaround on all of their projects and improve speed to market.

Estes Accelerator is Ready to Help – No Matter Where you Are in the Process

Whether it be a product idea with the details only still in your head, a rough paper napkin sketch, or an existing product that needs the kinks worked out, Estes Accelerator has the tools, ability, and experience to help make your project come to life. From product conception to full production and every step along the way, Estes Accelerator is ready to partner with you!

01 | Design Input – We believe the best results come from collaboration. It all begins with asking the right questions and then listening closely. Once we understand exactly what you need out of your product design, we provide thoughtful solutions to solve your design challenges.

02 | Conceptual Design – With a shared vision in place, we work closely with your engineering team to design concepts and create rough layouts of the product being produced. This allows us to collectively evaluate the planned look and functionality before investing time in the details.

03 | Detailed Design – Our design team starts to pull it all together and finalizes the details. Our goal is to use as few components as possible in our designs and ensure that they can be made economically as possible, which helps reduce cost, assembly time, and potential assembly defects.

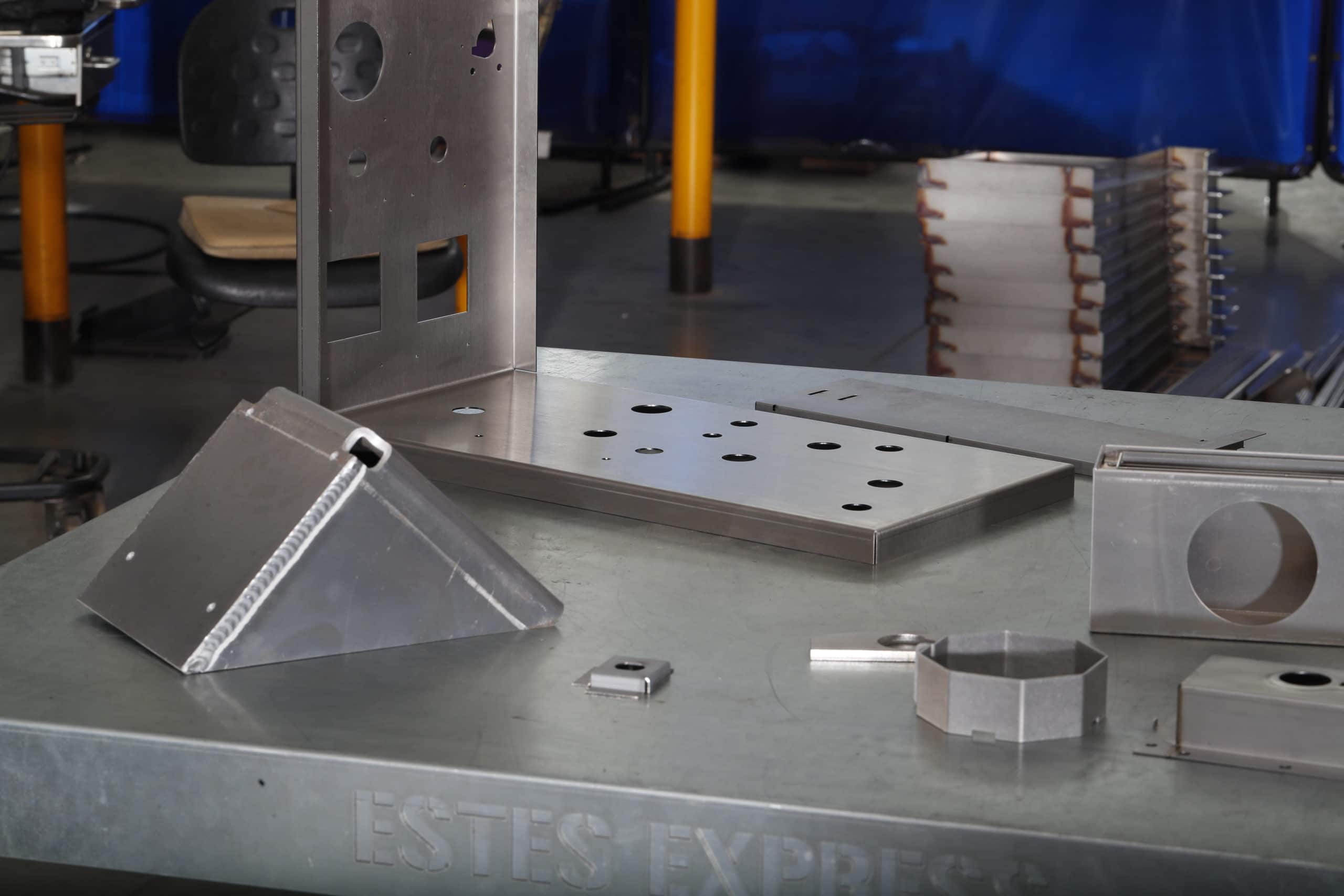

04 | Prototype – This is where the fun begins. We produce a fit and function prototype, allowing you to touch and test the product. If any issues arise, we resolve them quickly before going into production.

.

Estes Accelerator - Prototyping

What Can Estes Accelerator's Prototyping Services Do For You?

- Increase customers’ speed to market, utilizing dedicated equipment and personnel that doesn’t have to break into a production schedule

- Produce and refine prototypes from customers’ existing designs

- Transition products into full production

- Provide short-run manufacturing for quantities less than 50

Case Studies

Same Day Completion

THE CHALLENGE

A privately held international company was looking for a customized, aesthetically pleasing, finished piece to complement an existing prototype. After the previous manufacturer sent a broken piece, the company needed a quick delivery for a presentation. They needed a prototype shop they could trust.

SOLUTION

The company turned to Estes Accelerator for help. Estes Accelerator has its own equipment, which means there is no need to break into a full production schedule to move the project down the line.

RESULT

Typically, a project this size could take two weeks to finish. Having dedicated prototyping equipment ensured that Estes Accelerator could reorganize the schedule to accommodate the customer and deliver the completed unit the same day. For Estes, the customer comes first, and the prototyping shop makes every effort to exceed expectations.

.

Reducing Costs & Lead-Times

THE CHALLENGE

After searching for a reliable rapid prototype vendor, one of the largest packing equipment suppliers in the world came across Estes Accelerator – Product Development & Prototyping. This customer previously had issues with lead-time, reliability, and quality with other suppliers.

SOLUTION

Estes reduced the customer’s cost by 25% and the customer’s lead-time went from six weeks to ten days. By reducing the cost of the project through lean manufacturing, Estes can now handle the production run allowing the customer the opportunity to bring its fabrication back to the United States from overseas.

RESULT

The prototype phase typically took months, but Estes was able to reduce this phase to a matter of days. The Estes team worked with the customer from concept and design to a finished, fabricated, fully painted, working prototype. During the design phase, Estes helped the customer modify its current designs for better manufacturability (DFMA).

Advanced Technology Means Speed and Cost Savings

Let’s get your project quote started today.

Rapid Sheet Metal Prototyping & Product Development Equipment

Equipment includes: