CLIENT NEED

After searching for a reliable rapid prototype vendor, one of the largest packing equipment suppliers in the world came across Estes Accelerator – Product Development & Prototyping. This customer previously had issues with lead-time, reliability, and quality with other suppliers.

SOLUTION

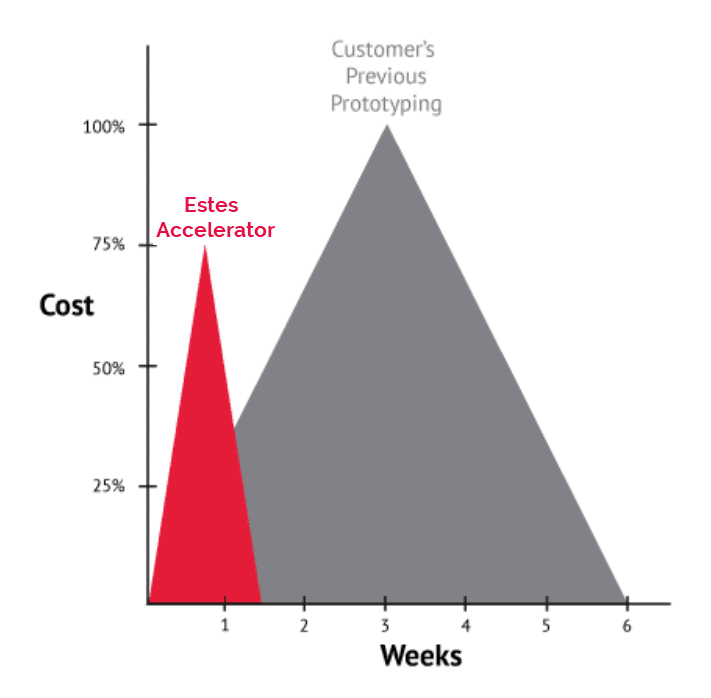

Estes reduced the customer’s cost by 25% and the customer’s lead-time went from six weeks to ten days. By reducing the cost of the project through lean manufacturing, Estes can now handle the production run allowing the customer the opportunity to bring its fabrication back to the United States from overseas.

RESULT

The prototype phase typically took months, but Estes was able to reduce this phase to a matter of days. The Estes team worked with the customer from concept and design to a finished, fabricated, fully painted, working prototype. During the design phase, Estes helped the customer modify its current designs for better manufacturability (DFMA).