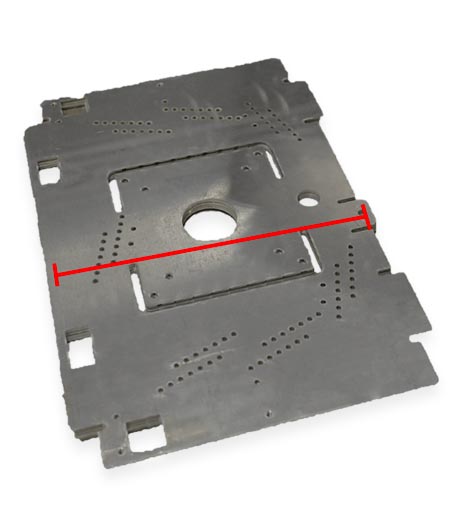

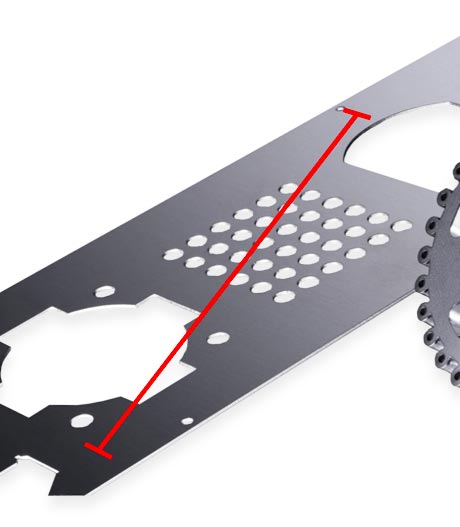

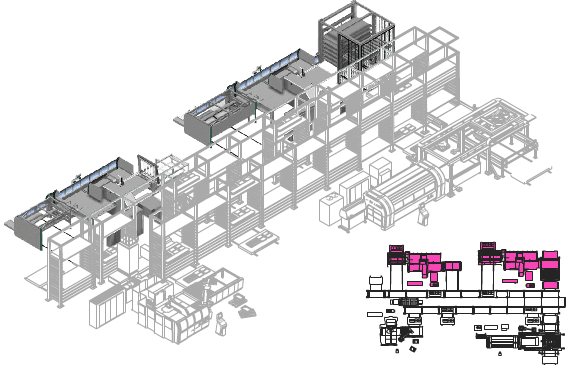

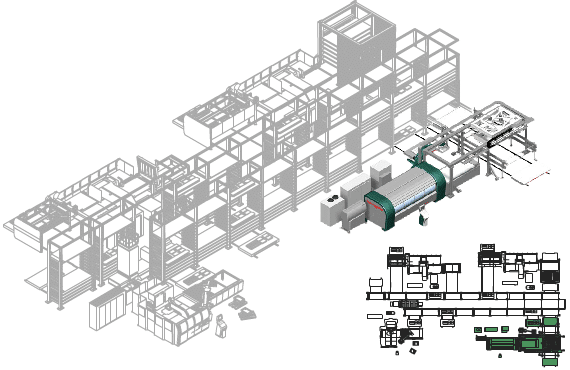

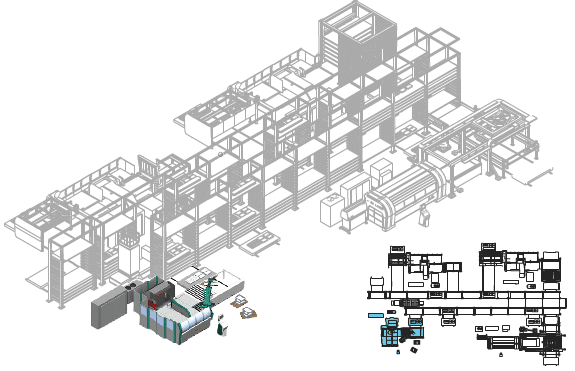

Automated Sheet Metal Fabrication

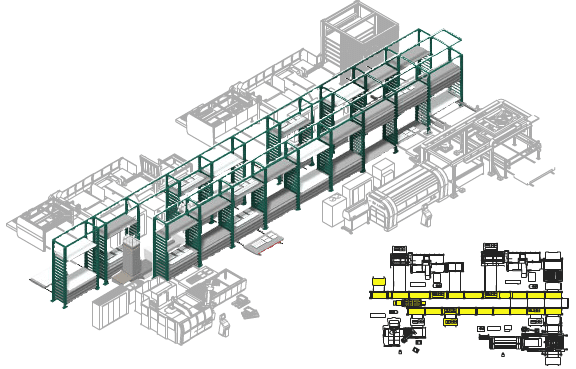

Max Velocity is Estes’ automated sheet metal fabrication cell powered by Salvagnini. Its automated nature and advanced technology provide exceptional quality, shorter lead times, and improved on-time delivery. It’s one of the most cost-effective solutions OEM manufacturers are using to solve today’s challenges.

The Estes Max Velocity takes cellular manufacturing to new levels. Every machine in the cell is fully automated, including the automatic storage and retrieval system – the MV Warehouse, which is the system’s backbone.

Maximize uptime and improve part accuracy and consistency while reducing lead times.