Read Estes Design & Manufacturing’s news, articles and resources on Lean Manufacturing.

Whether you are a “me-too” provider that offers cheaper versions of products already on the market, or your path to competitive success is through innovation of better products, value engineering can add value to your project and provide numerous benefits. What is Value Engineering? Value engineering is a systematic and organized approach used to…

No matter the size of your manufacturing environment, how you choose to organize each square foot of your facility can make a significant impact on the success of your organization. Cellular manufacturing has proven to provide many benefits to the companies that adopt this manufacturing style. Below we define cellular manufacturing and how it works,…

Amidst the many challenges brought on over the past year by the COVID-19 pandemic, the importance of innovation and lean manufacturing principles have become even more apparent. While 2020 was not the year for which most companies hoped or planned, it provided manufacturers with an opportunity to utilize lean manufacturing to address the shortages and…

Estes Philosophy: Continuous Improvement Over the past several months, we’ve shared three pillars of our philosophy, innovative thinking, people of high character and state-of-the-art technology. As a reminder, our philosophy at Estes Design and Manufacturing is to profitably produce fabricated metal products with a level of service and quality preferred by the customer. The fourth…

“Research suggests that manufacturers spend 30% to 50% of their time fixing errors and almost 24% of those errors are related to manufacturability,” according to Kashyap Vyas in Machine Design. That’s a lot of wasted material, time and money due to mistakes. The good news is by following principles of design for manufacturing (DFM) and…

Recently, Tim Estes, president of Estes Design and Manufacturing, attended the Lean Management Summit in Jacksonville, Florida. The Lean Management Summit seeks to bring organizational leaders to work in concert with one another to flow value across “silos” of the organization. “Many of the sessions I attended were centered on creating a lean culture” explains…

At Estes, we are focused on continuous improvement and lean initiatives. Lean initiatives opt to improve production, quality, and lead-time of operations in hopes of improving overall manufacturing. The end goal is to provide the highest quality product while continuing to meet demand and reducing waste in the process. Several lean tools are available to…

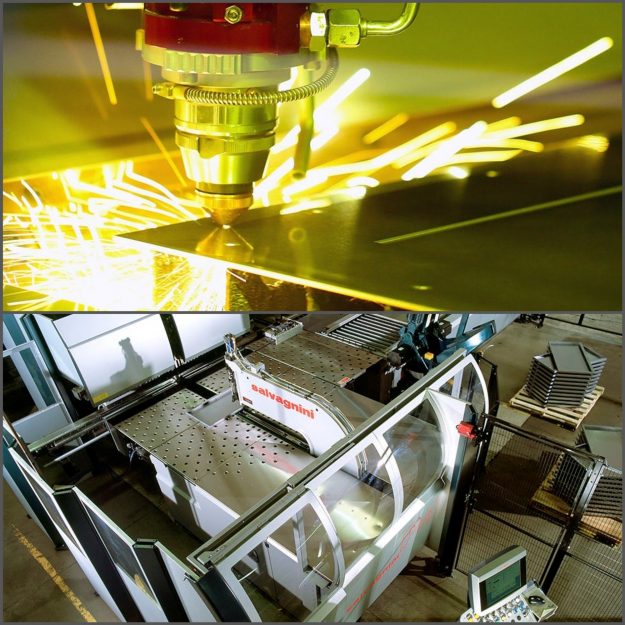

At Estes Design and Manufacturing, we use Salvagnini Panel Benders (see image) to provide lean and flexible production capabilities. When our customers allow us to utilize value engineering practices and tools it results in cost savings and value for the customer. Below are some of the benefits our customers receive based on our use of…

In February, we blogged about our Kaizen event, which is a highly focused workshop to take immediate action and improve existing processes within the company. While we’ve been focusing on “lean initiatives” for years, we recently contracted a company, Ro12 Enterprises, to guide us through the Kaizen event, assist with several projects, and provide on-going…

This month’s edition of The FABRICATOR features an interview by Tim Heston with Elizabeth Kautzmann, chairman of FMA’s Industrial Laser Council and laser program manager with FANUC FA America. In this “Conducting the Laser” article , Kautzmann emphasizes, “A system is only as strong as its weakest link – and in many cases, the laser…