Estes Design and Manufacturing continues to push the boundaries of prototyping with the addition of our Bambu Lab X1E polymer filament 3D printer. Since integrating this technology, Estes has used it to deliver faster, smarter, and more cost-effective solutions for both customer and in-house projects.

A Durable, Cost-Saving Solution for Our Customers

One of our first customer applications with the Bambu Lab X1E involved creating a plastic bumper that served as a cushion between a metal cart and another machine. Our customer was clear that the final part had to withstand two ongoing stressors:

1. Repeated impact

2. High heat from a germ-killing wash cycle

Before our 3D printing capability, the part would have gone through the complex machining process, which is more expensive and time-consuming.

With our 3D printer, we re-engineered the entire bumper design and consolidated what had been a two-piece assembly into a single component. We simplified the design, reduced overall material waste, and significantly cut back costs for our customers. The result of the streamlined process was a 95% decrease in part cost for the customer. Most importantly, we did it while also ensuring the bumper withstood the ongoing stressors.

Yes… We use it, too!

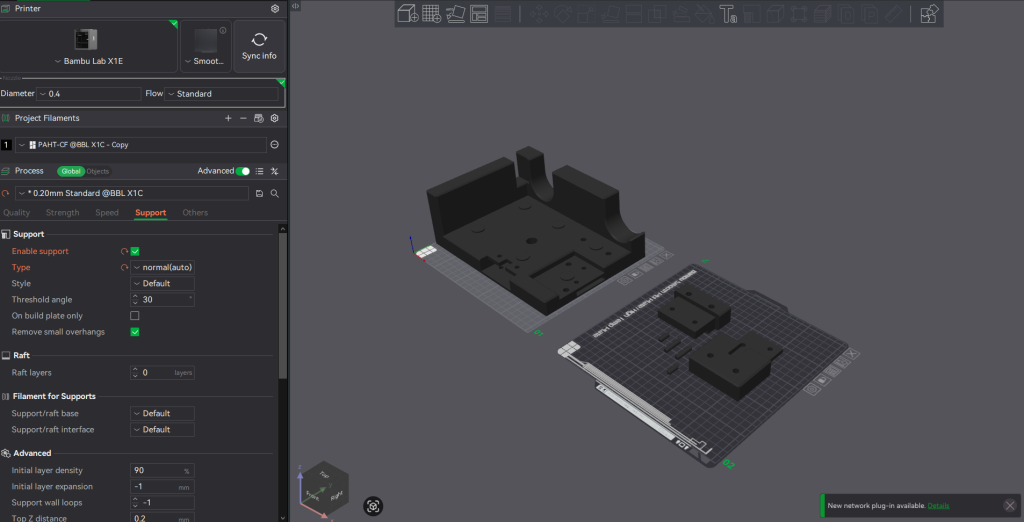

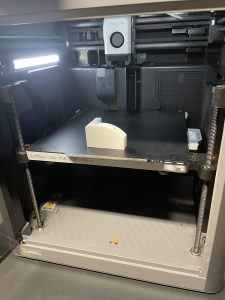

Around the same time our customer approached us to develop their bumper, we identified an opportunity to use the Bambu Lab X1E for one of our own production needs. After a revision to product plans, we needed to redesign a weld fixture used to locate studs on an end-use part. Rather than recreating the fixture using traditional machining, our team leveraged our 3D printer.

Using advanced engineered plastics, we designed the fixture in several interlocking sections, secured with heat inserts and bolts for added rigidity. Our problem-solving engineering approach worked around the printer’s build-plate parameters and produced a strong, lightweight fixture in record time. A project that would have taken multiple people and at least two weeks was completed by one person in under a week. The material and time cost savings were significant, and while our accounting team appreciated the reduced costs, what really matters is that this efficiency helps us deliver more value to our customers.

The Technology Behind the Results

The Bambu Lab X1E’s capabilities played a crucial role in both projects. Its precision, speed, and versatility, combined with a range of engineered materials, made it ideal for parts that required strength, durability, and heat resistance. Features like automatic bed leveling and filament changes streamlined the process, while the ability to print with over 20 filament types opened new design possibilities.

Advancing Innovation Through Additive Manufacturing

Beyond cost and time savings, 3D printing has become a powerful tool for Estes’ engineering and customer teams. It allows ideas to move quickly from concept to reality, enabling hands-on evaluation before committing to full-scale production. For our customers, that means faster development cycles at a much lower risk. For our business, it represents yet another way we’ve improved our overall efficiency and product quality.

As we expand additive manufacturing services, we will put our Bambu Lab X1E to work for fixture development, prototyping, and low-volume production. It has proven itself as an integral part of our commitment to use state-of-the-art technology for the customer’s benefit.