Read Estes Design & Manufacturing’s industry news articles here.

Your reputation with your customers depends in part on the quality of the products you provide to them. So it goes without saying that the work your metal fabricator delivers—whether it is a component or a completed product—becomes a reflection of you. Choosing a sheet metal fabrication partner can be a challenging task. There are…

You have a sheet metal fabrication project to complete. Maybe you’ve done this a hundred times before, or maybe this is your first project order, and you are a little intimidated by where to start. An excellent way to alleviate a lot of stress is to bring your sheet metal fabrication partner in during the…

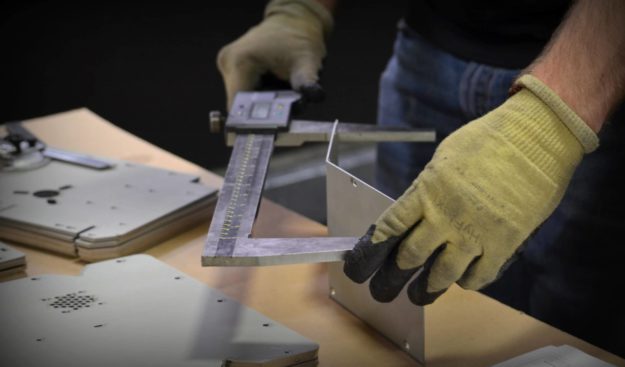

One of the first steps in getting your sheet metal fabrication project into production is to set a budget and gather quotes from your potential fabrication partners. Before you choose a partner, however, you will want to understand the factors that influence the estimate given to you. There are numerous elements that affect a quote…

3D printing is becoming increasingly popular and uses a process called additive manufacturing, which “uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes,” (GE.com). This is in contrast with traditional sheet metal fabrication, which uses machining, laser cutting, punching, and other processes…

You have your project plans, you’ve gathered quotes from metal fabricators, and now you’re ready to pick your new supplier. FabShop XYZ catches your eye…their estimate is much lower than the others. Great! Actually, maybe not so great. Cost is an important factor, and finding ways to reduce costs has never been more important as…

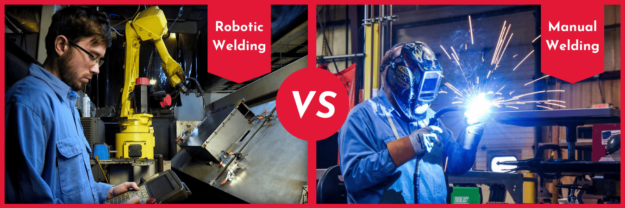

In metal fabrication, welding is a central requirement that can be done either manually or automatically. What are the advantages of each method? Is robotic or manual welding the best choice for your project? There are several advantages to robotic welding in a project. Robotic welding is: More efficient: Welding robots are often promoted…

With so many factors causing prices to skyrocket, many OEMs and contractors are looking for ways to cut costs with their products. Several potential cost-saving evaluations should be performed before your project even gets to a fabricator: your ordering practices, your product design, and which fabricator you chose. The decisions that you make concerning these…

Have you checked out our new Resources website page? As a design and innovation leader in the sheet metal fabrication industry, it’s important for us to make information regarding our services and trends easily accessible for our current and prospective clients. In an effort to share our knowledge and expertise in the industry, we have…

Estes Design and Manufacturing is excited to launch our 3D Laser Welding Whitepaper series. These whitepapers will be written by our very own resident expert, Jay Reddick. Jay has been with Estes since the beginning. In 2009, when Estes decided to invest in leading-edge technology in the laser welding market, Jay was integral in the…

How Are Panel Benders Different From Press Brakes? While the press brake has been the go-to bending machine for many years, depending on the part, the panel bender can have several advantages over the traditional press brake. Machine Set Up The most apparent difference between a press brake and a panel bender is the…