Read Estes Design & Manufacturing’s industry news articles here.

“It goes without saying that no company, small or large, can win over the long run without energized employees who believe in the mission and understand how to achieve it.” Jack Welch, former CEO and chairman of General Electric Indianapolis Star Names Estes Design & Manufacturing a Winner of the Central Indiana Top Workplaces…

Press brakes (or brake presses) are some of the most common machines used by sheet metal fabricators and have been the go-to bending machines for many years. Press brakes are powerful machines that are capable of forming both simple and complex parts. While there are dozens of different press brakes in various sizes and each…

Laser-cutting technology has revolutionized the manufacturing industry, providing unparalleled precision and efficiency in cutting a wide range of materials in sheet metal manufacturing. One such material that has gained popularity in recent years is vinyl-coated stainless steel. This unique product combines the durability and strength of stainless steel with the versatility and aesthetics of vinyl…

While polymers and plastics have started to be more widely used in medical product designs and applications, metals and specifically sheet metal fabrication are still highly beneficial to the medical industry. Metals serve as the building blocks to many of the life-saving medical devices and equipment doctors, nurses, and patients rely on every day and…

Whatever your sheet metal fabrication project may be, you need confidence that it will be completed quickly, efficiently, and correctly. Outsourcing work overseas is a popular solution, especially in our increasingly globalized world. Technology has created an ever increasing global marketplace, and it’s easy to take for granted how simple things like email and video…

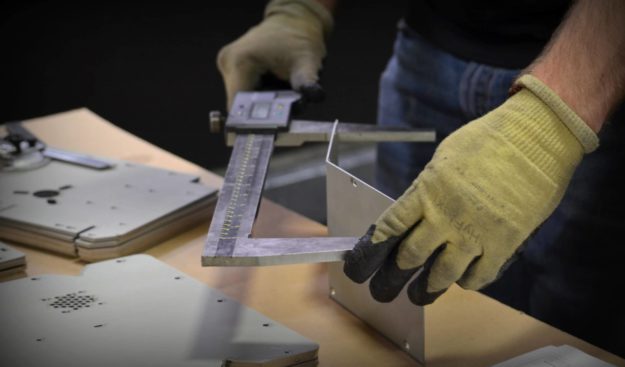

Your reputation with your customers depends in part on the quality of the products you provide to them. So it goes without saying that the work your metal fabricator delivers—whether it is a component or a completed product—becomes a reflection of you. Choosing a sheet metal fabrication partner can be a challenging task. There are…

You have a sheet metal fabrication project to complete. Maybe you’ve done this a hundred times before, or maybe this is your first project order, and you are a little intimidated by where to start. An excellent way to alleviate a lot of stress is to bring your sheet metal fabrication partner in during the…

One of the first steps in getting your sheet metal fabrication project into production is to set a budget and gather quotes from your potential fabrication partners. Before you choose a partner, however, you will want to understand the factors that influence the estimate given to you. There are numerous elements that affect a quote…

3D printing is becoming increasingly popular and uses a process called additive manufacturing, which “uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes,” (GE.com). This is in contrast with traditional sheet metal fabrication, which uses machining, laser cutting, punching, and other processes…

You have your project plans, you’ve gathered quotes from metal fabricators, and now you’re ready to pick your new supplier. FabShop XYZ catches your eye…their estimate is much lower than the others. Great! Actually, maybe not so great. Cost is an important factor, and finding ways to reduce costs has never been more important as…